Thermal One-Part Hybrids

HT4500

Thermal conductivity liquid gap fillers have the benefits of shape recovery, strong material cohesion, and good long-term thermal stability — they also offer a very low thermal resistance comparable to thermal grease, and can fill gaps at interfaces.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

Typical Applications

- Consumer electronics

- Telecommunications equipment

- Automotive electronics

- Power supplies & semiconductors

- Memory & power modules

- Power electronics Features

- High thermal performance and low contact resistance

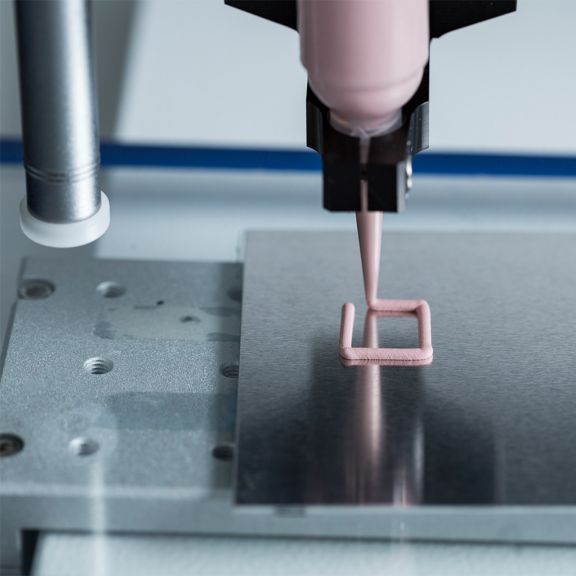

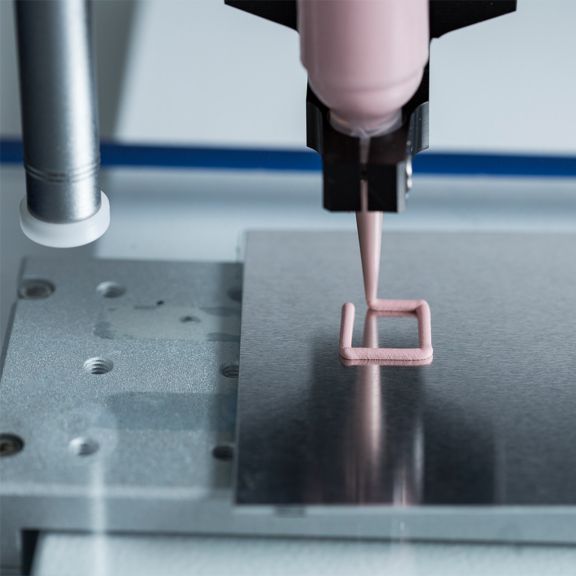

- Easily dispensable and reworkable

- High compressibility for low stress applications Long-term reliability

- No pump-out or cracking risk

- Reduced oil separation

- Requires no mixing, additional curing or low temperature storage

Physical Properties

- Color

- Green

- Cure Schedule

- Pre-cured

- Shelf Life

- 6 months Year

- Specific Gravity

- 3.3, Test Method ASTM D792

Thermal Properties

- Thermal Conductivity

- 4.5 W/m-K, Test Method, ASTM D5470

Electrical Properties

- Volume Resistivity

- >1.0X1013 ohm-cm, Test Method ASTM D257

Temperature

- Storage Temperature

- RT

Other

- Other Notes

- 5 KV/mm, Test Method D149 Dielectric Strength

General Information

- Application

- Automation Gap Filler

- Key Features

- High compressibility for low stress applications

- High thermal performance and low contact resistance

- Long-term reliability

- No pump-out or cracking risk

- Reduced oil separation

- Typical Uses

- Consumer electronics

- Memory & power modules

- Power electronics

- Power supplies

- Telecommunications equipment

Physical Properties

- Color

- Green

- Cure Schedule

- Pre-cured

- Shelf Life

- 6 months Year

- Specific Gravity

- 3.3, Test Method ASTM D792

Thermal Properties

- Thermal Conductivity

- 4.5 W/m-K, Test Method, ASTM D5470

Electrical Properties

- Volume Resistivity

- >1.0X1013 ohm-cm, Test Method ASTM D257

Temperature

- Storage Temperature

- RT

Other

- Other Notes

- 5 KV/mm, Test Method D149 Dielectric Strength

General Information

- Application

- Automation Gap Filler

- Key Features

- High compressibility for low stress applications

- High thermal performance and low contact resistance

- Long-term reliability

- No pump-out or cracking risk

- Reduced oil separation

- Typical Uses

- Consumer electronics

- Memory & power modules

- Power electronics

- Power supplies

- Telecommunications equipment

- Specific Gravity : 3.3, Test Method ASTM D792

- Shelf Life : 6 months Year

- Color : Green

- Thermal Conductivity : 4.5 W/m-K, Test Method, ASTM D5470

- Cure Schedule : Pre-cured

- Volume Resistivity : >1.0X1013 ohm-cm, Test Method ASTM D257

- Storage Temperature : RT

- Other Notes : 5 KV/mm, Test Method D149 Dielectric Strength

- Typical Uses : Consumer electronics|Memory & power modules|Power electronics|Power supplies|Telecommunications equipment

- Key Features : High compressibility for low stress applications|High thermal performance and low contact resistance|Long-term reliability|No pump-out or cracking risk|Reduced oil separation

- Application : Automation Gap Filler