Thermal Two-Part Hybrids

HLT3500

Honeywell HLT series products are two-component cured-in-place dispensable gap fillers could be easily dispensed w/good thixotropic characteristics and low viscosity, provides the high compressibility and excellent long term reliability. (3.5 W/m·K)

Physical Properties

- Color

- Part A: White, Part B: Blue

- Cure Schedule

- 12 hours at 25 °C

- 30 min at 100 °C

- Shelf Life

- 6 months Year

- Specific Gravity

- 3.2, Test Method ASTM D792

- Viscosity

- 300000-450000 cps, Test Method ASTM D2196 (Brookfield Viscometer, #7 spindle, 10 rpm)

Thermal Properties

- Thermal Conductivity

- 3.5 W/m-K, Test Method ASTM D5470

- Thermal Impedance

- 0.44 °C·in²/W, 1 mm at 10 psi, Typical Value, Test Method D5470

General Information

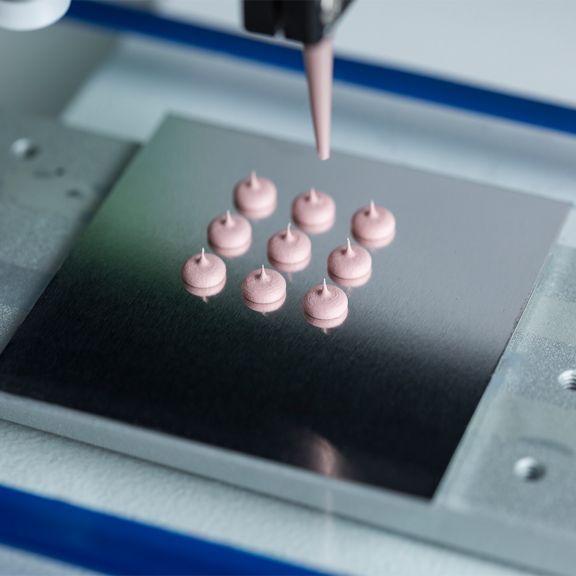

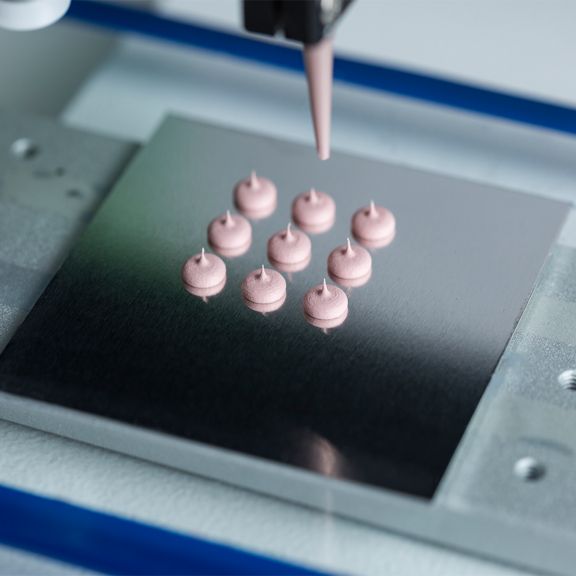

- Application

- Automation Gap Filler

- Key Features

- High compressibility for low stress applications

- Long-term reliability

- Low contact resistance

- No pump-out and cracking

- Reduced oil separation

- Typical Uses

- Consumer electronics

- Memory & power modules

- Telecommunications equipment

Physical Properties

- Color

- Part A: White, Part B: Blue

- Cure Schedule

- 12 hours at 25 °C

- 30 min at 100 °C

- Shelf Life

- 6 months Year

- Specific Gravity

- 3.2, Test Method ASTM D792

- Viscosity

- 300000-450000 cps, Test Method ASTM D2196 (Brookfield Viscometer, #7 spindle, 10 rpm)

Thermal Properties

- Thermal Conductivity

- 3.5 W/m-K, Test Method ASTM D5470

- Thermal Impedance

- 0.44 °C·in²/W, 1 mm at 10 psi, Typical Value, Test Method D5470

General Information

- Application

- Automation Gap Filler

- Key Features

- High compressibility for low stress applications

- Long-term reliability

- Low contact resistance

- No pump-out and cracking

- Reduced oil separation

- Typical Uses

- Consumer electronics

- Memory & power modules

- Telecommunications equipment

- Shelf Life : 6 months Year

- Color : Part A: White, Part B: Blue

- Viscosity : 300000-450000 cps, Test Method ASTM D2196 (Brookfield Viscometer, #7 spindle, 10 rpm)

- Thermal Impedance : 0.44 °C·in²/W, 1 mm at 10 psi, Typical Value, Test Method D5470

- Cure Schedule : 12 hours at 25 °C|30 min at 100 °C

- Thermal Conductivity : 3.5 W/m-K, Test Method ASTM D5470

- Specific Gravity : 3.2, Test Method ASTM D792

- Typical Uses : Consumer electronics|Memory & power modules|Telecommunications equipment

- Application : Automation Gap Filler

- Key Features : High compressibility for low stress applications|Long-term reliability|Low contact resistance|No pump-out and cracking|Reduced oil separation