Thermal One-Part Hybrids

HT4500

Thermal conductivity liquid gap fillers have the benefits of shape recovery, strong material cohesion, and good long-term thermal stability — they also offer a very low thermal resistance comparable to thermal grease, and can fill gaps at interfaces.

Typical Applications

- Consumer electronics

- Telecommunications equipment

- Automotive electronics

- Power supplies & semiconductors

- Memory & power modules

- Power electronics Features

- High thermal performance and low contact resistance

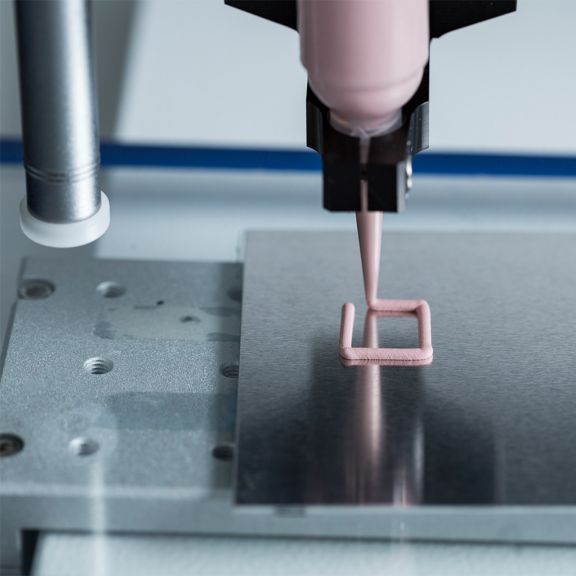

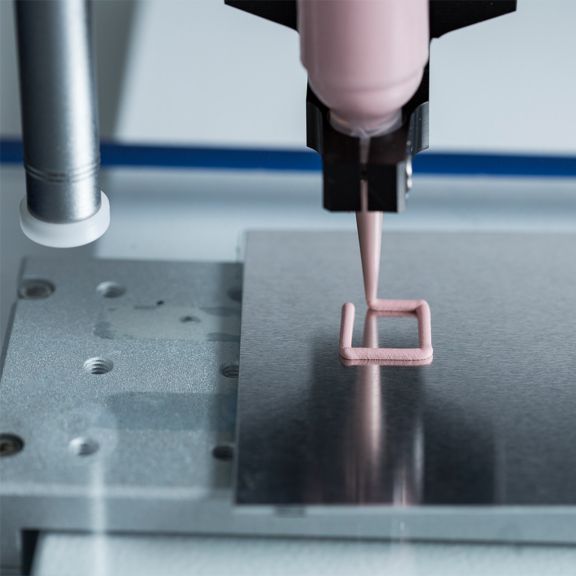

- Easily dispensable and reworkable

- High compressibility for low stress applications Long-term reliability

- No pump-out or cracking risk

- Reduced oil separation

- Requires no mixing, additional curing or low temperature storage

Thermal Properties

- Thermal Conductivity

- 4.5 W/m-K, Test Method, ASTM D5470

Physical Properties

- Color

- Green

- Cure Schedule

- Pre-cured

- Shelf Life

- 6 months Year

- Specific Gravity

- 3.3, Test Method ASTM D792

Electrical Properties

- Dielectric Strength

- 5 KV/mm, Test Method D149

- Volume Resistivity

- >1.0X1013 ohm-cm, Test Method ASTM D257

Temperature

- Storage Temperature

- RT

General Information

- Application

- Automation Gap Filler

- Key Features

- High compressibility for low stress applications

- High thermal performance and low contact resistance

- Long-term reliability

- No pump-out or cracking risk

- Reduced oil separation

- Typical Uses

- Consumer electronics

- Memory & power modules

- Power electronics

- Power supplies

- Telecommunications equipment

Thermal Properties

- Thermal Conductivity

- 4.5 W/m-K, Test Method, ASTM D5470

Physical Properties

- Color

- Green

- Cure Schedule

- Pre-cured

- Shelf Life

- 6 months Year

- Specific Gravity

- 3.3, Test Method ASTM D792

Electrical Properties

- Dielectric Strength

- 5 KV/mm, Test Method D149

- Volume Resistivity

- >1.0X1013 ohm-cm, Test Method ASTM D257

Temperature

- Storage Temperature

- RT

General Information

- Application

- Automation Gap Filler

- Key Features

- High compressibility for low stress applications

- High thermal performance and low contact resistance

- Long-term reliability

- No pump-out or cracking risk

- Reduced oil separation

- Typical Uses

- Consumer electronics

- Memory & power modules

- Power electronics

- Power supplies

- Telecommunications equipment

- Thermal Conductivity : 4.5 W/m-K, Test Method, ASTM D5470

- Cure Schedule : Pre-cured

- Specific Gravity : 3.3, Test Method ASTM D792

- Shelf Life : 6 months Year

- Color : Green

- Dielectric Strength : 5 KV/mm, Test Method D149

- Volume Resistivity : >1.0X1013 ohm-cm, Test Method ASTM D257

- Storage Temperature : RT

- Typical Uses : Consumer electronics|Memory & power modules|Power electronics|Power supplies|Telecommunications equipment

- Key Features : High compressibility for low stress applications|High thermal performance and low contact resistance|Long-term reliability|No pump-out or cracking risk|Reduced oil separation

- Application : Automation Gap Filler