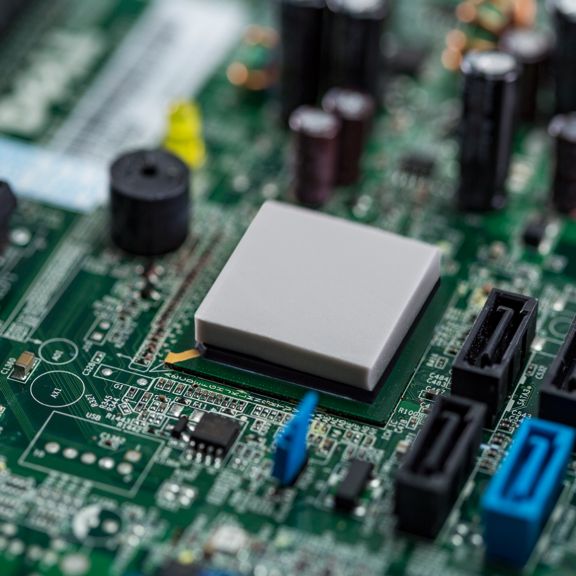

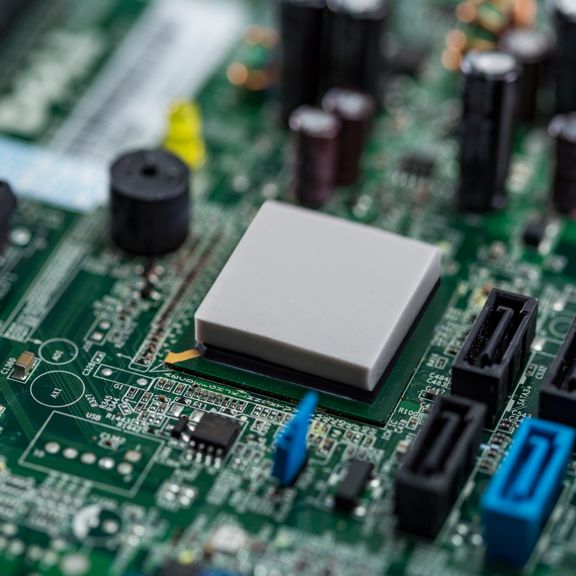

Thermal Gap Filler Pads

TGP6000

Excellent surface wetting designed for low contact resistance. Naturally tacky, and requires no additional adhesive which could inhibit thermal performance. (Grey color, 0.25 Thermal Impedance, 6.0 Thermal Conductivity, Hardness 40 on Shore 00)

Physical Properties

- Color

- Grey

- Hardness

- 40 Shore00, Test Method ASTM D2240

- Shelf Life

- 12 months Year

- Specific Gravity

- 3.3, Test Method ASTM D792

- Thickness (mm)

- 0.5-5, Test Method ASTM D374

Thermal Properties

- Thermal Conductivity

- 6.0 W/m-K, Test Method ASTM D5470

- Thermal Impedance

- 0.25 °C·in²/W, 1 mm at 10 psi, Typical Value, Test Method ASTM D5470

Flammability Properties

- Flammability

- V-0, Test Method UL94

Electrical Properties

- Dielectric Constant

- 8.5 at 1MHz, Test Method ASTM D150

- Volume Resistivity

- 3.79x1015 ohm-cm, Test Method ASTM D257

General Information

- Application

- High Compressibility

- Key Features

- Low Oil Bleeding

Physical Properties

- Color

- Grey

- Hardness

- 40 Shore00, Test Method ASTM D2240

- Shelf Life

- 12 months Year

- Specific Gravity

- 3.3, Test Method ASTM D792

- Thickness (mm)

- 0.5-5, Test Method ASTM D374

Thermal Properties

- Thermal Conductivity

- 6.0 W/m-K, Test Method ASTM D5470

- Thermal Impedance

- 0.25 °C·in²/W, 1 mm at 10 psi, Typical Value, Test Method ASTM D5470

Flammability Properties

- Flammability

- V-0, Test Method UL94

Electrical Properties

- Dielectric Constant

- 8.5 at 1MHz, Test Method ASTM D150

- Volume Resistivity

- 3.79x1015 ohm-cm, Test Method ASTM D257

General Information

- Application

- High Compressibility

- Key Features

- Low Oil Bleeding

- Shelf Life : 12 months Year

- Hardness : 40 Shore00, Test Method ASTM D2240

- Thickness (mm) : 0.5-5, Test Method ASTM D374

- Thermal Conductivity : 6.0 W/m-K, Test Method ASTM D5470

- Specific Gravity : 3.3, Test Method ASTM D792

- Color : Grey

- Thermal Impedance : 0.25 °C·in²/W, 1 mm at 10 psi, Typical Value, Test Method ASTM D5470

- Flammability : V-0, Test Method UL94

- Dielectric Constant : 8.5 at 1MHz, Test Method ASTM D150

- Volume Resistivity : 3.79x1015 ohm-cm, Test Method ASTM D257

- Application : High Compressibility

- Key Features : Low Oil Bleeding