Phase Change Materials

PTM7950

PTM7950 is a Phase Change Pad with a Thermal Impedance of 0.04 - 0.08 (°C cm²/w), Thermal Conductivity of 8.5 (w/mk) and Specific Gravity of 2.8 (g/cm³)

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

Connect with our team to learn more and evaluate Honeywell’s PTM7950, which is a highly thermally conductive Phase Change Material (PCM), engineered for:

- Minimizing thermal resistance at interfaces

- Maintaining excellent performance

- Providing scalable application at a competitive cost

This proprietary material provides superior reliability (pass 150˚C baking 1000 hours, T/C-B 1000 cycles) and maintains low thermal impedance (<0.04˚Ccm2/W @ no shim), making the PTM7950 series desirable for high performance integrated circuit devices.

We invite you to evaluate PTM7950 for your applications, including:

- Power modules/inverters in automotive and power applications

- High-performance IT/enterprise computing devices

- Consumer electronics, high-performance IC

- High power LED

- PTM7950 Pad | Easy application and no drying steps

- PTM7950-SPS | Paste version with slow-drying solvent

- PTM7950-SP | Paste version for automatic stencil printing

- High performance filler and polymer technology

- Silicone-free, no pump out, bleed out, dry out issues

- Highly conductive filler loading to optimize performance

- Industry-proven superior long-term reliability

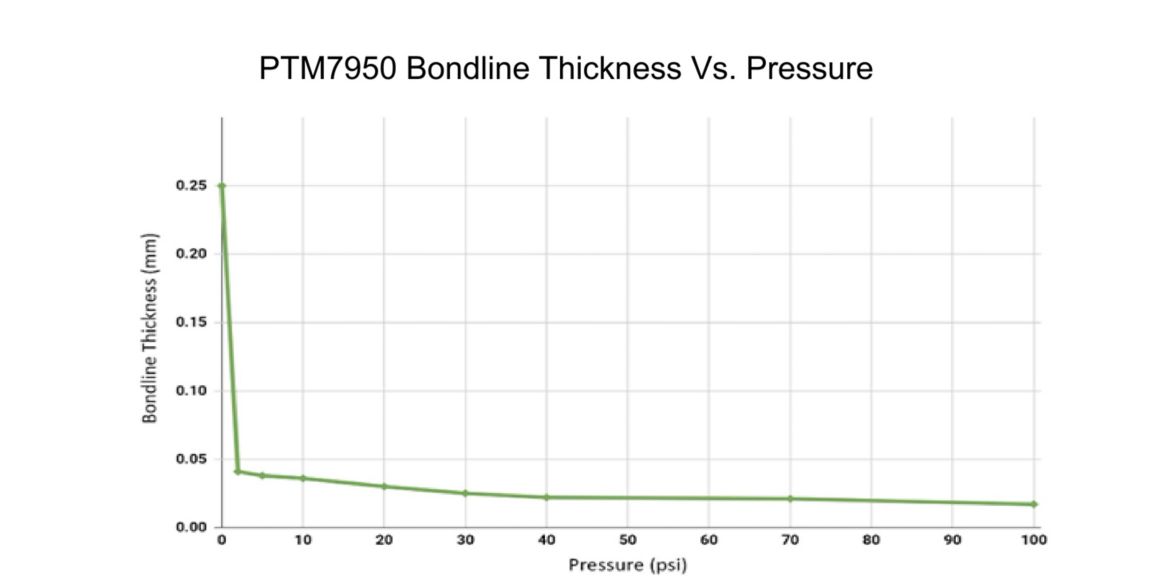

- Min BLT~20um, typical BLT is below 50um

- 30~40 psi pressure is needed for usage

Achieving thin bondline and great thermal performance by minimum pressure application

One of the key characteristics of PTM7950 is its bondline thickness, which refers to the thickness of the layer of adhesive between two surfaces being bonded. Please refer to the chart-PTM7950 Bondline Thickness vs. Pressure in the thumbnail to learn more about changes in PTM7950 BLT (mm) under varying pressure conditions (psi).

As the pressure applied to PTM7950 increases, the bondline thickness decreases. Specifically, a minimum pressure of 10 psi is needed to observe a significant reduction in bondline thickness. This means that lower pressure is sufficient to achieve a thinner bondline, which can be advantageous in certain applications.

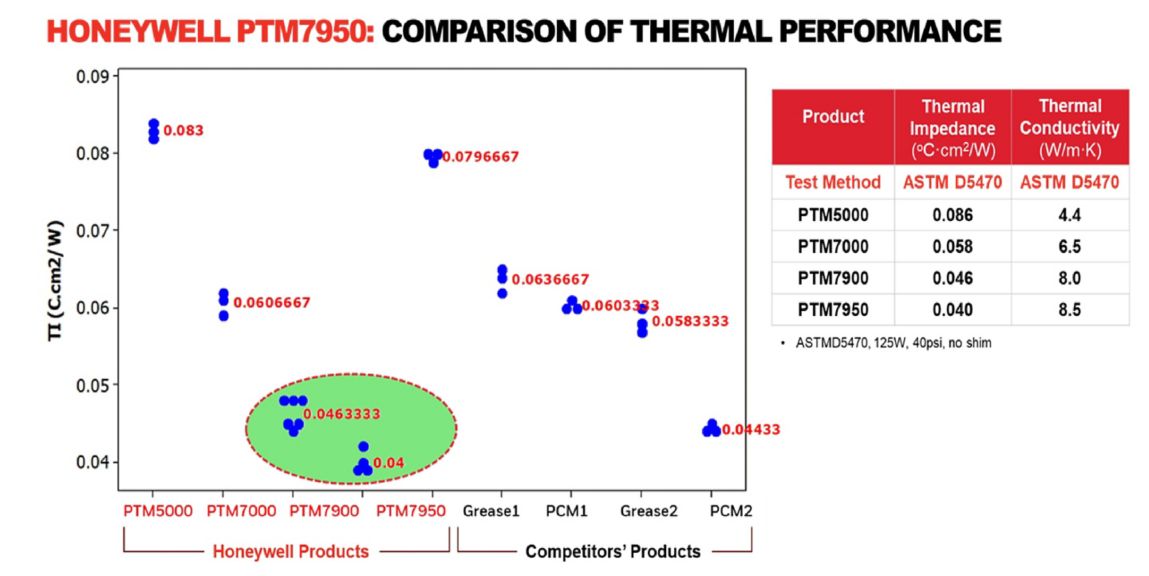

PTM7950 is best-in-class against other thermal materials

Refer to chart-Honeywell PTM7950: Comparison of thermal performance (click on the thumbnails to enlarge), where thermal impedance values for various materials is shown, including that of PTM7950 and PTM7900. Both of these materials have the lowest thermal impedance values when compared to all other materials tested, including competitive thermal greases. Overall, the PTM 7950 is the top performer among all materials tested for thermal impedance.

The PTM 7950 is clearly the best choice for thermal impedance, with the lowest value among all materials tested. This makes it an excellent option for electronic devices that require exceptional thermal management.

Get in touch with our experts to learn more.

Physical Properties

- Bond-Line Thickness (BLT)

- 0.038

- Color

- Grey

- Shelf Life

- 12 months Year

- Specific Gravity

- 2.8 g/cm3, Test Method ASTM D374

- Thickness (mm)

- 0.2

- 0.25

- 0.3

- 0.4

- 0.5

- Viscosity

- N/A

- Liner Color

- Light

- Format

- Pad

Thermal Properties

- Thermal Conductivity

- 8.5 W/m-K, Test Method ASTM D5470

- Thermal Impedance

- 0.04-0.08 at no shim °C cm²/w, Test Method ASTM D5470 Modified

General Information

- Application

- Base Station

- CPU

- GPU

- Optical

- Switch

- Thin Bondline

- Transceiver

- Key Features

- High Reliability

- Low TI

- Sub-segment

- Networks

- Notebook

- PC

- Tablet

- Industry

- Consumer Electronics

- Technology and Telecommunications

Other

- Other Notes

- Pads available in sheets and rolls

Physical Properties

- Bond-Line Thickness (BLT)

- 0.038

- Color

- Grey

- Shelf Life

- 12 months Year

- Specific Gravity

- 2.8 g/cm3, Test Method ASTM D374

- Thickness (mm)

- 0.2

- 0.25

- 0.3

- 0.4

- 0.5

- Viscosity

- N/A

- Liner Color

- Light

- Format

- Pad

Thermal Properties

- Thermal Conductivity

- 8.5 W/m-K, Test Method ASTM D5470

- Thermal Impedance

- 0.04-0.08 at no shim °C cm²/w, Test Method ASTM D5470 Modified

General Information

- Application

- Base Station

- CPU

- GPU

- Optical

- Switch

- Thin Bondline

- Transceiver

- Key Features

- High Reliability

- Low TI

- Sub-segment

- Networks

- Notebook

- PC

- Tablet

- Industry

- Consumer Electronics

- Technology and Telecommunications

Other

- Other Notes

- Pads available in sheets and rolls

- Viscosity : N/A

- Thickness (mm) : 0.2|0.25|0.3|0.4|0.5

- Thermal Impedance : 0.04-0.08 at no shim °C cm²/w, Test Method ASTM D5470 Modified

- Thermal Conductivity : 8.5 W/m-K, Test Method ASTM D5470

- Specific Gravity : 2.8 g/cm3, Test Method ASTM D374

- Shelf Life : 12 months Year

- Liner Color : Light

- Format : Pad

- Color : Grey

- Bond-Line Thickness (BLT) : 0.038

- Application : Base Station|CPU|GPU|Optical|Switch|Thin Bondline|Transceiver

- Sub-segment : Networks|Notebook|PC|Tablet

- Key Features : High Reliability|Low TI

- Industry : Consumer Electronics|Technology and Telecommunications

- Other Notes : Pads available in sheets and rolls